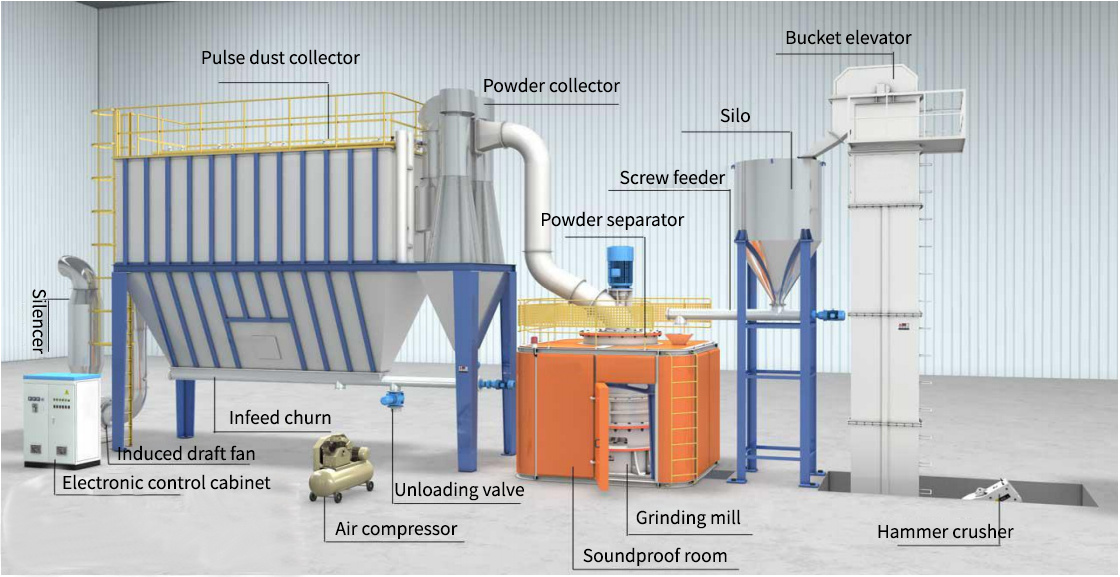

Granite Grinding Mill

Feed size:

≤20mm

Fineness:

150 mesh-3000 mesh adjustable

Production Capacities:

2.8-20t / h

隐藏域元素占位

Material

It can be widely applied to non-flammable and explosive brittle materials with Mohs hardness <6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, and more than 100 kinds of materials.

Application

Popular among aggregates, highway construction, railway construction, airport building and some other industries.

PRODUCT ADVANTAGE

Better shape

Large grading interval and high precision. The product particle size is good and stable, which is the ideal equipment for the current dry production of non-metallic mineral fine powder.

Intelligent Control

Through the binding of cell phones and WeChat, you can realize SMS or WeChat to receive data feedback

Environmentally Friendly And Energy-Saving

More environmental protection and energy saving: production under negative pressure, with high efficient and enlarged dust collector, less dust in the working environment.

Ring Roll Mill

Forced turbine classification system particle size uniformity, fine, easy to realize the finished product fineness between 150 mesh-3000 mesh arbitrary adjustment.

PRODUCT PROFILE

Granite is a kind of natural stone ore, pure granite does not contain metal, so the ore is also called non-metallic ore, its comprehensive utilization value is very high, with the domestic demand for this kind of stone ore continues to increase, its application field is also gradually increasing, at present the main application in the field of construction, building materials, chemical industry, engineering and so on.

The main minerals are quartz, potassium feldspar and acidic plagioclase feldspar, while the secondary minerals are black mica, hornblende, and sometimes a small amount of pyroxene. There are many kinds of secondary minerals, common ones are magnetite, titanite, zircon, apatite, tourmaline, fluorite and so on. The quartz content is the more abundant of the various magmatic rocks, and its content can range from 20-50%, with a few up to 50-60%.

Previous :

Next:

Related Cases

Technical Parameters

Main specification | |||

| Model | LXM80 | LXM100 | LXM125 |

| Ring Diameter(mm) | 800 | 1000 | 1250 |

| Ring Number(layer) | 3 | 4 | 4 |

| Roller Number(piece) | 18-21 | 28-36 | 30-40 |

| Main Shaft Speed(r.p.m) | 230-240 | 180-200 | 135-155 |

| Input Size(mm) | ≤20 | ≤20 | ≦20 |

| Finished Size(um/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 100-6 (150-2000) |

| Capacity(t/h) | 0.5-4.5 | 1-9 | 2.8-20 |

| Overall Dimension(L*W*H,m) | 13.9*4*6.2 | 18*4.6*8.6 | 14*9*10.25 |

-

It can be widely applied to non-flammable and explosive brittle materials with Mohs hardness <6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, and more than 100 kinds of materials.

-

Popular among aggregates, highway construction, railway construction, airport building and some other industries.

-

Large grading interval and high precision. The product particle size is good and stable, which is the ideal equipment for the current dry production of non-metallic mineral fine powder.

-

Through the binding of cell phones and WeChat, you can realize SMS or WeChat to receive data feedback

-

More environmental protection and energy saving: production under negative pressure, with high efficient and enlarged dust collector, less dust in the working environment.

-

Forced turbine classification system particle size uniformity, fine, easy to realize the finished product fineness between 150 mesh-3000 mesh arbitrary adjustment.

-

Main specification

Model LXM80 LXM100 LXM125 Ring Diameter(mm) 800 1000 1250 Ring Number(layer) 3 4 4 Roller Number(piece) 18-21 28-36 30-40 Main Shaft Speed(r.p.m) 230-240 180-200 135-155 Input Size(mm) ≤20 ≤20 ≦20 Finished Size(um/mesh) 74-5

(200-2500)74-5

(200-2500)100-6

(150-2000)Capacity(t/h) 0.5-4.5 1-9 2.8-20 Overall Dimension(L*W*H,m) 13.9*4*6.2 18*4.6*8.6 14*9*10.25

Get In Touch With Us

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

Phone/WhatsApp:

Email:

About Us

We are always committed to industrial grinding equipment, providing high-grade grinding solutions and high-end complete sets of equipment for large-scale projects in mining, construction, building materials, chemical industry and so on.

HUATAO GROUP

Email:wangzeng@cnleixin.com

Tel/WhatsApp:+86-18624933999

Add: No.3 Chaoyang Road, Zhitian Development Zone, Zhengzhou, Henan, China

Get In Touch With Us!

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.