Barite Ultra-fine Grinding Mill

Feed size:

≤20mm

Fineness:

200-2500μm/mesh

Production Capacities:

0.5-4.5t / h

隐藏域元素占位

Material

It can be widely applied to non-flammable and explosive brittle materials with Mohs hardness <6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, and more than 100 kinds of materials.

Application

Popular among aggregates, highway construction, railway construction, airport building and some other industries.

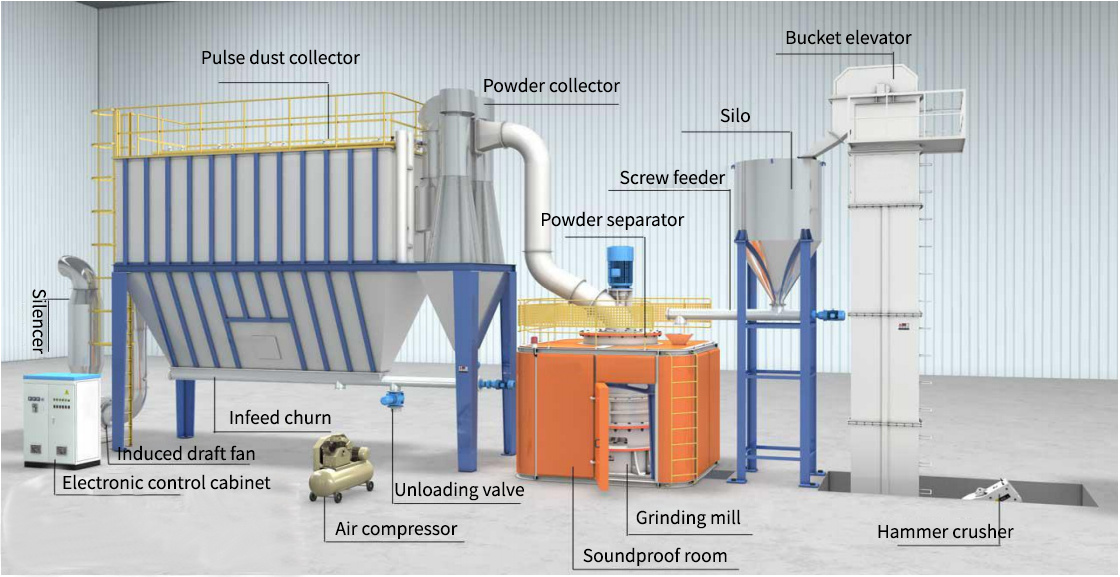

PRODUCT ADVANTAGE

Better shape

Large grading interval and high precision. The product particle size is good and stable, which is the ideal equipment for the current dry production of non-metallic mineral fine powder.

Intelligent Control

Through the binding of cell phones and WeChat, you can realize SMS or WeChat to receive data feedback

Environmentally Friendly And Energy-Saving

More environmental protection and energy saving: production under negative pressure, with high efficient and enlarged dust collector, less dust in the working environment.

Ring Roll Mill

Forced turbine classification system particle size uniformity, fine, easy to realize the finished product fineness between 150 mesh-3000 mesh arbitrary adjustment.

PRODUCT PROFILE

Baryte Ultra-Fine Grinding Mill (also known as Calcite Micropowder Mill, Limestone Micropowder Mill, Calcium Carbonate Micropowder Mill, Talc Micropowder Mill, Baryte Micropowder Mill, Gypsum Micropowder Mill, Marble Micropowder Mill, Feldspar Micropowder Mill, fluorite micro powder mill) is primarily suitable for the ultra-fine grinding of medium to low hardness, non-flammable and non-explosive brittle materials with a Mohs hardness of ≤6, such as calcite, chalk, limestone, dolomite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, chlorite, vermiculite, sepiolite, attapulgite, diatomite, barite, gypsum, alum shale, graphite, fluorite, phosphate ore, potassium ore, pumice, and over 100 other materials. The finished powder particle size can be adjusted between 325 and 3000 mesh, with a production capacity of 0.4 to 4.5 tons per hour.

Related Cases

Technical Parameters

|

Main specification |

|||

|

Model |

LXM80 |

LXM100 |

LXM125 |

|

Ring Diameter(mm) |

800 |

1000 |

1250 |

|

Ring Number(layer) |

3 |

4 |

4 |

|

Roller Number(piece) |

18-21 |

28-36 |

30-40 |

|

Main Shaft Speed(r.p.m) |

230-240 |

180-200 |

135-155 |

|

Input Size(mm) |

≤20 |

≤20 |

≤20 |

|

Finished Size(μm/mesh) |

74-5 (200-2500) |

74-5 (200-2500) |

100-6 (150-2000) |

|

Capacity(t/h) |

0.5-4.5 |

1-9 |

2.8-20 |

|

Overall Dimension(L*W*H,m) |

13.9*4*6.2 |

18*4.6*8.6 |

14*9*10.25 |

-

It can be widely applied to non-flammable and explosive brittle materials with Mohs hardness <6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, and more than 100 kinds of materials.

-

Popular among aggregates, highway construction, railway construction, airport building and some other industries.

-

Large grading interval and high precision. The product particle size is good and stable, which is the ideal equipment for the current dry production of non-metallic mineral fine powder.

-

Through the binding of cell phones and WeChat, you can realize SMS or WeChat to receive data feedback

-

More environmental protection and energy saving: production under negative pressure, with high efficient and enlarged dust collector, less dust in the working environment.

-

Forced turbine classification system particle size uniformity, fine, easy to realize the finished product fineness between 150 mesh-3000 mesh arbitrary adjustment.

-

Main specification

Model

LXM80

LXM100

LXM125

Ring Diameter(mm)

800

1000

1250

Ring Number(layer)

3

4

4

Roller Number(piece)

18-21

28-36

30-40

Main Shaft Speed(r.p.m)

230-240

180-200

135-155

Input Size(mm)

≤20

≤20

≤20

Finished Size(μm/mesh)

74-5 (200-2500)

74-5 (200-2500)

100-6 (150-2000)

Capacity(t/h)

0.5-4.5

1-9

2.8-20

Overall Dimension(L*W*H,m)

13.9*4*6.2

18*4.6*8.6

14*9*10.25

Get In Touch With Us

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

Phone/WhatsApp:

Email:

About Us

We are always committed to industrial grinding equipment, providing high-grade grinding solutions and high-end complete sets of equipment for large-scale projects in mining, construction, building materials, chemical industry and so on.

HUATAO GROUP

Email:wangzeng@cnleixin.com

Tel/WhatsApp:+86-18624933999

Add: No.3 Chaoyang Road, Zhitian Development Zone, Zhengzhou, Henan, China

Get In Touch With Us!

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.